Fuel Economy defined

What is your fleet's fuel efficiency?

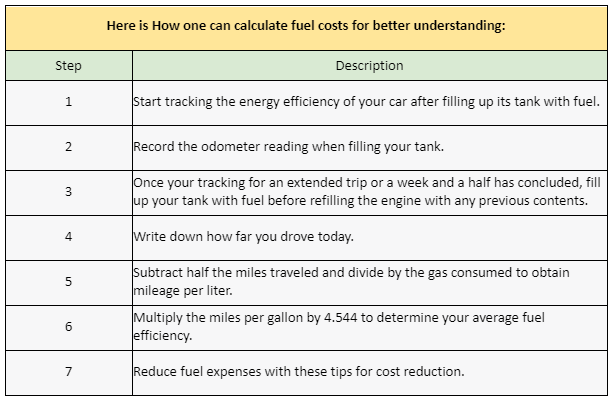

How can one calculate fuel costs?

Follow these steps to calculate the costs of fuel in your vehicle:

1. Start tracking the energy efficiency of your car after filling up its tank with fuel.

2. Record the odometer reading when filling your tank.

3. Once your tracking for an extended trip or a week and a half has concluded, fill up your tank with fuel before refilling the engine with any previous contents.

4. Write down how far you drove today.

5. Subtract half the miles traveled and divide by the gas consumed to obtain mileage per liter.

6. Multiply the miles per gallon by 4.544 to determine your average fuel efficiency.

7. Reduce fuel expenses with these tips for cost reduction.

What is Predictive Maintenance?

How to Improve Fleet Uptime?

Here are the 7 Proactive Strategies for Improving Fleet Uptime:

1. To improve fleet uptime, it is essential to provide superior customer satisfaction, run an efficient operation, and maintain profitability. Last mile delivery time being so crucial, any vehicle downtime could have serious repercussions for success – but with proper measures and technologies implemented, you can effectively mitigate downtime, ensuring deliveries arrive on schedule.

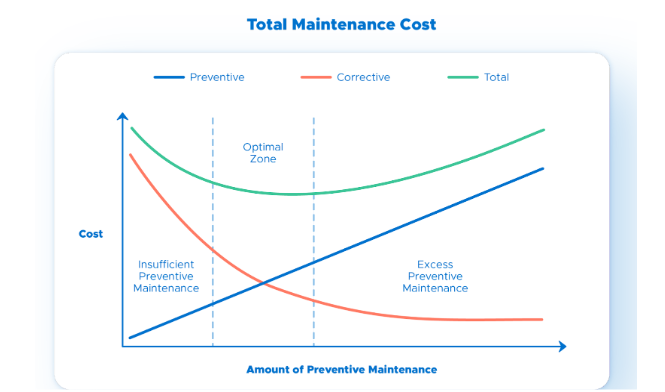

2. Due to global economic factors like rising oil prices,chip shortages and labor shortages affecting the repair industry, fleets face increasing maintenance costs that impair uptime. Luckily, with an effective preventive fleet management solution and comprehensive onboard diagnostics solution, fleet managers can increase uptime to decrease operational downtime.

3. Proactive fleet maintenance strategies involve staying current with recommended services for your vehicles to ensure their optimal operation. Preventative maintenance is an invaluable strategy for minimizing downtime costs. It allows fleets to identify and address minor issues before they escalate further, which helps significantly lower repair costs while also helping minimize unplanned repairs that might impede operations.

4. Reactive fleet maintenance focuses on fixing problems as they arise, which may help lower downtime costs but is both expensive and unreliable. Fleet managers might spend too much time dousing fires instead of stopping them before they even begin! To combat this problem, fleets should utilize predictive maintenance, which detects various deterioration signs with condition monitoring tools to anticipate when components will likely break down and provide preventive maintenance at just the right moment.

5. An effective vehicle inspection checklist is an integral component of preventive maintenance planning. By customizing one to your fleet’s needs and operating environment, creating a vehicle inspection checklist will help maximize uptime while cutting costs. When developing such a list, consider freight types transported and their operating conditions and input from drivers and maintenance technicians regarding what should be included.

6. Preventive maintenance programs play an essential role in ensuring inspections are performed on schedule, so keeping track of each fleet unit to ensure inspections occur on schedule can be key to their success. A telematics fleet management system can be used to keep tabs on vehicles’ progress and provide accurate reports in real-time – for instance, a vehicle activity report details daily activities, including usage, operator, and mileage for each truck while harsh events reports can highlight when hard driving has caused stress to its components and how this has an impactful consequence for its components.

7. Fleet managers should develop an organized process for managing state and federal inspections. Digitalizing all inspection records makes the task simpler, while using a telematics solution can automatically notify drivers about impending reviews or MOTs so repairs can be completed before their deadline and prevent unnecessary downtime.