Fleet uptime is essential to customer satisfaction, efficient operation, and profitability. A single vehicle off the road can significantly delay deliveries and stop productivity; luckily, intelligent solutions are available to increase fleet uptime through better driver training and performance enhancement.

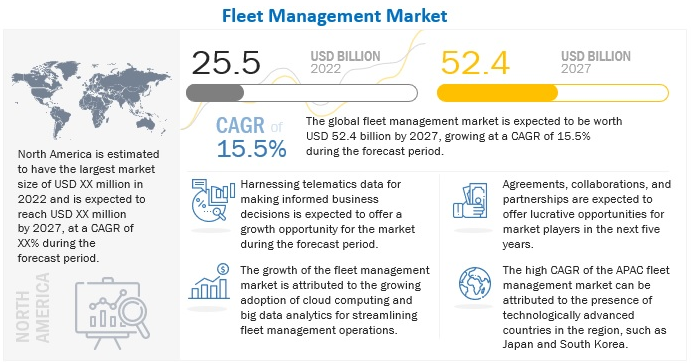

Fleet managers can reduce maintenance costs and driver downtime by using technology to monitor equipment health, optimize routes and enhance fuel efficiency. Retention managers can use these insights to make informed decisions that reduce maintenance costs and enhance profitability thanks to the widespread adoption of advanced telematics technologies that provide data about maintenance, emissions, idling speed, safety features, and driver behaviors.

According to Taabi, all newly hired drivers must receive comprehensive initial and retraining to maximize uptime and avoid downtime. This is vital to ensuring their competence and safety when driving at high speeds – such as HPDE courses on racetracks that teach driving techniques so drivers can operate their vehicles to their fullest potential 32% of GPS tracking users reported a constructive ROI in lesser than 6 months in 2021.

1. Types of Driver Performance Analysis System

As computer applications have grown increasingly complex, fine-tuning them manually has become more challenging. Various automated analysis techniques have been created to address these difficulties, and these tools can typically be classified as static, dynamic, or hybrid mechanisms for analysis. This article offers an in-depth examination of available analysis tools beginning with simple static techniques before moving toward advanced dynamic mechanisms to gather application performance data.

Static analysis tools (STs) can pinpoint application performance bottlenecks by inspecting its code structure. Unfortunately, this tool may be inconvenient because a timing system requires regular interruptions to collect performance data.

Dynamic Analysis Tools (DATs) allow applications to gather performance information by injecting analysis routines directly into target programs while they run. DATs typically rely on hardware counters which monitor an application in real-time and provide statistics on key aspects of its operation, making DATs easier than STs but sometimes inconvenient due to sudden performance hits when injecting an analysis routine.

Hybrid analysis tools (HCTs) combine the benefits of both STs and DATs into one software tool. HCTs usually employ an execution wrapper that configures kernel modules and sampling mechanisms before targeting an application under test; then, free running application while samples of system state are taken periodically and recorded at predefined intervals [Kufrin05b]. HCTs can often address a wide range of performance issues since they collect extensive statistics at all levels of an application’s hierarchy of functionality.

2. Driver Behavior Model

Driver behavior refers to all intentional and unintentional actions, emotions, and decisions while operating a motor vehicle. It can be affected by internal factors like fatigue, drowsiness, and driving attitudes as well as external ones like road traffic conditions and environmental hazards; bad driver behaviors like aggressive driving and speeding should be restricted as these behaviors have detrimental impacts on other road users’ safety and should be curtailed accordingly.

Driver behavior is an elusive phenomenon that is difficult to grasp and predict. While current theories attempt to comprehensively explain drivers’ actions (risk homeostasis models and task-difficulty homeostasis models, for instance), these explanations often fall short due to lacking specificity for understanding driving.

To develop a generalizable model, the cost function must be defined to be independent of the driving environment and task difficulty. To accomplish this goal, a sliding time window was employed to identify driving behaviors using vehicle kinematic and expression data, labeled by consideration of outside ambient video information and thresholds set on vehicle kinematics thresholds. Five types of driving behaviors were identified: lane keeping, acceleration-deceleration turning, and lane change was observed in this study.

Driver scoring solutions enable businesses to monitor driver behavior, reduce instances of speeding, idling, and other violations of Service Level Agreements (SLAs), improve fuel efficiency for greater business performance, encourage healthy competition among drivers via rewards and recognition programs, as well as save costs related to vehicle costs and insurance premiums.

3. Driver Safety

Driver safety is a fundamental concept to grasp for drivers. It encompasses the skills and behaviors needed to keep you aware and prepared for any situation on the road, no matter who might be at fault. These include following all traffic rules, avoiding distractions, keeping adequate spacing between vehicles, and keeping an eye out for changing weather conditions; safely knowing when it is necessary to turn off cruise control and slow down when confronted by wet roads or other roadway hazards is part of being an expert driver.

Driving distracted is a leading cause of accidents, so drivers must know how to prevent and manage distractions while behind the wheel. With wireless phones ringing or navigation systems providing directions, even experienced drivers may become easily distracted behind the wheel – this is why many state laws now mandate drivers put their cell phones on silent and place it out of reach while driving.

Aggressive driving should also be avoided, which includes speeding, sudden lane changes, and running red lights. If you observe someone engaging in aggressive driving behavior, slow down and pull over safely when safe.

As drivers of commercial trucks must abide by road rules and be mindful of their larger sizes, drivers should heed any special precautions necessary. Since trucks take longer to stop than other vehicles, leave sufficient distance between your car and any oncoming truck ahead.

4. Driver Tracking

Driver Tracking involves observing and tracking fleet drivers’ driving styles, performance levels, and locations with GPS tracking technology. This enables managers to make last-minute adjustments and complete orders on time – an integral component of any delivery logistics operation whose absence could mean missed growth opportunities for businesses.

Increased Revenue: Driver tracking’s key advantage lies in increasing safety while decreasing costs by curbing risky driving behaviors. When drivers know they’re being monitored, they tend to drive more carefully, avoiding speeding, unsafe turning, and unnecessary idling that can add up over time. Tracking data also allows managers to identify areas where drivers require further training or incentive and recognition programs to drive safer behavior – aggressive driving increases maintenance and repair expenses.

Ascertaining a driver’s current location makes it easier for dispatchers to recall them for priority deliveries, address an urgent situation on the road, and notify customers about their ETA to ensure they’re home when their package arrives.

ELDs (electronic logging devices) are required by US and Canadian federal HOS regulations for long-haul carriers to comply with HOS regulations. However, driver-tracking software offers a complementary view of fleet operations in real time. With features like route optimization and proof of delivery verification, this software helps reduce fuel consumption, decrease downtime, and prevent late deliveries.

5. Driver Management

Driver management involves overseeing and overseeing a fleet of drivers to ensure compliance with company policies while aiding their performance at work. This could involve tracking driver performance metrics, vehicle condition checks, and on-time delivery reports and offering support when necessary.

Driver management done right won’t put your drivers under a microscope–instead, it should allow for efficient interactions that allow them to do their jobs effectively. Two-way communication is key for building strong professional relationships, and being transparent about the ways you evaluate and provide regular feedback will go a long way toward keeping drivers happy and contented with their jobs. Fleets that publicly make all their evaluation methods and standards available could prevent unnecessary driver dissatisfaction from developing within their ranks.

As part of driver management, one essential aspect is monitoring each load as it passes from vehicle to vehicle in your supply chain. Thankfully, GPS tracking and telematics data collected by each vehicle allow this monitoring process, eliminating potential blind spots in operations and optimizing fleet operations.

Some fleet management systems offer driver coaching technology features, providing audio notifications after every safety incident. These alerts motivate drivers by reinforcing positive behaviors and reminding them they are held accountable for their performance.

6. Maximize UpTime With Fleet Maintenance

Fleet maintenance entails keeping trucks and trailers on the road as much as possible to maximize revenue and customer satisfaction, thus saving money in lost revenue and customer dissatisfaction. Thus, every fleet manager aims to take every measure to reduce downtime and repair costs as much as possible.

Investing in a fleet management partner who can serve multiple roles is one of the best ways to ensure work trucks run efficiently. Your maintenance partner should understand what makes your equipment tick; have close ties with OEMs; and stay up-to-date with all training available so they can provide fleet maintenance tips to maximize mileage on parts and equipment.

One key strategy for Taabi to optimize fleet uptime is investing in technology that supports informed maintenance decisions. Telematics solutions, for instance, can give you an overall picture of your entire fleet and help identify problems quickly – such as engine fault codes – to prevent costly downtime.

We establish a system to enable you to tailor checklists to different equipment pieces, particularly trucks, and trailers with special upfits like refrigeration units or APUs. Making a personalized checklist tailored specifically to these unique requirements ensures you won’t overlook any critical inspection items on any machinery.